FAP-BIOTECH

Filtre à particules et catalyseur complètement saturés ? Hydro Ecotech, la solution dédiée aux professionnels et aux industriels.

*Hors frais de démontage/remontage (250 € HT) et hors frais d’expédition/livraison (80 € HT).

Pourquoi choisir FAP BIO-TECH ?

✅ Un service clé en main avec prise en charge rapide et efficace.

✅ Un nettoyage écologique, grâce à l’utilisation d’additifs biodégradables et un procédé sans produits chimiques agressifs.

✅ Une solution économique, permettant d’éviter le remplacement coûteux d’un FAP.

✅ Une conformité avec les normes antipollution, en réduisant drastiquement les émissions de particules fines.

Avec FAP BIO-TECH, offrez une seconde vie à vos filtres à particules, améliorez la performance de vos véhicules et réduisez votre empreinte environnementale en toute simplicité.

FAP BIO-TECH : Régénération Écologique et Optimisée de Vos Filtres à Particules

FAP BIO-TECH est notre service de nettoyage et régénération des filtres à particules (FAP), conçu pour garantir une performance moteur optimale, une réduction des émissions polluantes et une durée de vie prolongée de vos équipements. Grâce à une technologie écologique et performante, nous éliminons efficacement les suies et résidus tout en respectant les normes environnementales en vigueur.

Un Service Clé en Main avec Collecte & Livraison

Nous assurons la prise en charge complète de votre FAP, avec une solution simple, rapide et efficace :

✔ Collecte du FAP directement dans votre atelier, partout en France.

✔ Régénération complète, avec un rapport de test détaillé avant et après intervention.

✔ Traitement des paroies de protection par nanotechnologie pour éviter une nouvelle saturation dans le temps

✔ Retour rapide du FAP régénéré dans votre atelier.

✔ Frais de transport/logistique : 69 € (hors gabarit : +30 kg ou +2,5 m).

Notre Processus de Régénération en 4 Étapes

1️⃣ Nettoyage sous pression : Injection d’air comprimé et d’eau chaude, associée à des additifs biodégradables, en circuit fermé pour un nettoyage écologique et sans risque.

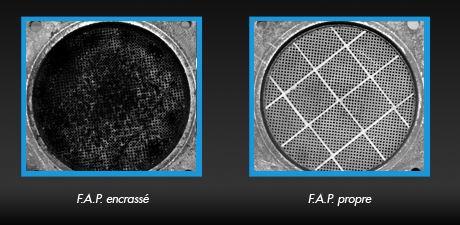

2️⃣ Élimination des particules fines : Désencrassage en profondeur des cloisons microporeuses des canaux du filtre, éliminant suies, cendres et impuretés.

3️⃣ Séchage minutieux : Séchage contrôlé pour garantir une réutilisation immédiate et une performance optimale.

4️⃣ Contrôle & Certification : Fourniture d’un rapport de régénération détaillé, incluant les mesures de contre-pression avant et après intervention.

Les causes filtre à particules ou catalyseur saturé

Encrassement

Souvent dans certains cas, lorsque le filtre à particules et le catalyseur sont complètement saturés (tel est le cas chez la RTM pour une partie des bus), notre solution de l’injection par l’hydrogène ne peut traiter le problème avec résultat car la calamine et la suie encombre, à force d’accumulation, se transforment en charbon sec et dur.

Les professionnels sont souvent exposés à ce problème. Il faut qu’il les fasse démontés et expédier dans un centre spécialisé et agrée pour le nettoyage de polluant aux alentours du nord de la France. Soit le client commande un FAP neuf chez le constructeur entre 2500 et 3500 euros soit il le fait nettoyer. (Délais postaux et délai de traitement allée et retour)

Frais engagés

La prestation est facturée entre 900 et 1200€ plus la perte de productivité du camion immobilisé au minimum 3 à 4 semaines. Souvent, quand ils ne peuvent pas réaliser la prestation, ils renvoient au client un filtre à particules adaptable, et qui n’est pas une pièce d’origine, ce qui pose problème car le client peut perdre la garantie constructeur.

*Vidéo réalisé en atelier

Prestation terminée = FAP ou catalyseur retrouvé

Une fois la prestation sur place terminé, le FAP ou le catalyseur est remonté, le véhicule peut prendre la route. (Valable pour les camions, voitures, bus, bennes à ordure, BTP, matériels agricoles…) tout ce qui est moteur thermique et industriel.

Pour tout devis ou informations veuillez nous contacter par mail ou par appels dans la page contact –>.

NOUVEAU : BAR-ZEL, l’additif révolutionnaire pour une décarbonation écologique et performante

BAR-ZEL est un additif innovant, écologique et non inflammable, développé en collaboration avec le bureau d’études de la société saoudienne Aramco. Il a été conçu pour optimiser la combustion, réduire les émissions polluantes et améliorer les performances moteur.

Destiné aux moteurs thermiques maritimes et terrestres, BAR-ZEL est compatible avec tous les types de carburants. Grâce à sa formule concentrée, 1 litre d’additif permet de traiter 1 000 litres de carburant, garantissant ainsi une efficacité optimale tout en contribuant à une réduction significative de l’empreinte environnementale.

Une Technologie Brevetée, Sécurisée et Certifiée

- Normes ISO 9001, 14001, 45001 et certification Intertek Europe.

- 100 % sûr : Non corrosif, sans risque pour le moteur et l’environnement.

- Facile d’utilisation : Ajoutez BAR-ZEL dans le réservoir et roulez !

- Un investissement rentable : Moins de carburant, plus de performance.

- BAR-ZEL : L’additif nouvelle génération pour une mobilité plus propre et plus efficace.

Pastilles

✅ Nettoie en profondeur

✅ Réduit les émissions polluantes

✅ Restaure les performances moteur

✅ Économie de carburant

Liquide

Technologie brevetée et certifiée par le Ministère des Transports et les bureaux Veritas