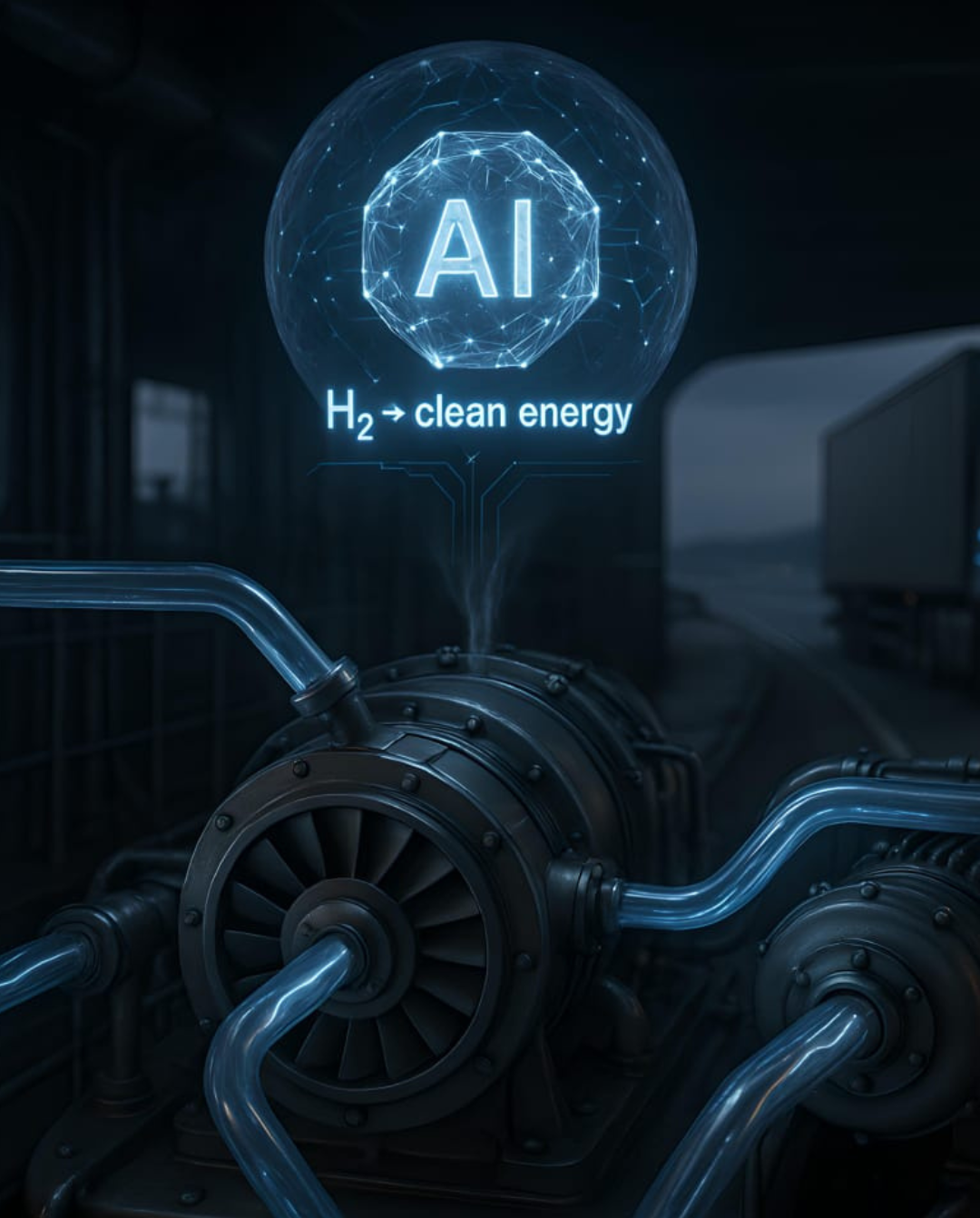

Nos générateur d’hydrogène hybride I.A pour décarboner vos moteurs thermiques et générer vos crédits carbones.

Fumée noire, voyants allumés, trous à l’accélération…

Dans plus de 75% des cas, le coupable est l’encrassement de votre moteur dû à la calamine.

**Voir conditions auprès des garages partenaires

HybridOgen® IA

Générateur Embarqué & Connecté

Résultats & Gains

Pollution

FAP

Turbo

Soupapes

*Nos dispositifs sont conçus pour être totalement écologique et neutre vis-à-vis du moteur : ils n’altèrent en rien son fonctionnement et n’ont aucune incidence sur la garantie constructeur !

Puissance

Retrouvez vos performances d’origine moteur jusqu’à + 65%

Pollution

En baisse de -30% à -65% des émissions nocives et C02

Économies

Fini les réparations et immobilisations coûteuses. -50% de consommation d’AD BLUE

Consommation

Entre -20% et –40%

( GARANTIS ) par plein de carburant.

Eco-conduite -8%

Additifs -10%

Bilan carbone certifié

Atteignez vos objectifs de décarbonation avec un bilan carbone certifié qui vous permettra d’obtenir des crédits carbone Co2

BAR-ZEL – Optimisez la combustion, réduisez les émissions

1 litre traite 1000 litres de carburant

Nanotechnologie et Décarbonation : Une Révolution pour Tous les Moteurs Thermiques

Grâce aux avancées en nanotechnologie, notre additif carburant non inflammable, disponible sous forme de pastille ou de liquide, offre une solution innovante, universelle et multitâche pour tous les moteurs thermiques : essence, diesel, hybride, GNR et pour tout type de carburant : BioFioul, HVO, E-Fuels

Une action en profondeur pour une combustion propre et optimisée

✅ Nanotechnologie active : agit au niveau moléculaire pour optimiser la combustion, réduisant drastiquement les particules fines, les impuretés et la fumée noire.

✅ Décarbonation efficace : nettoie et protège l’ensemble des organes mécaniques du moteur (injecteurs, turbo, admission, vanne EGR, catalyseur, FAP).

✅ Optimisation énergétique : améliore la puissance du moteur, facilite le démarrage à froid et réduit la consommation de carburant.

✅ Sans intervention mécanique : pas besoin de démontage, le traitement s’effectue directement via le carburant.

✅ Séparation de l’eau et carburant à l’intérieur du reservoir.

Une solution certifiée et conforme aux normes internationales

Notre additif répond aux normes ISO 9001, ISO 14001 et ISO 45001, et bénéficie d’une certification Intertek Europe, garantissant sécurité, efficacité et respect des réglementations environnementales.

Scientifiquement prouvé

Économiquement validé

Performance prouvée

Comment fonctionne

la décarbonation ?

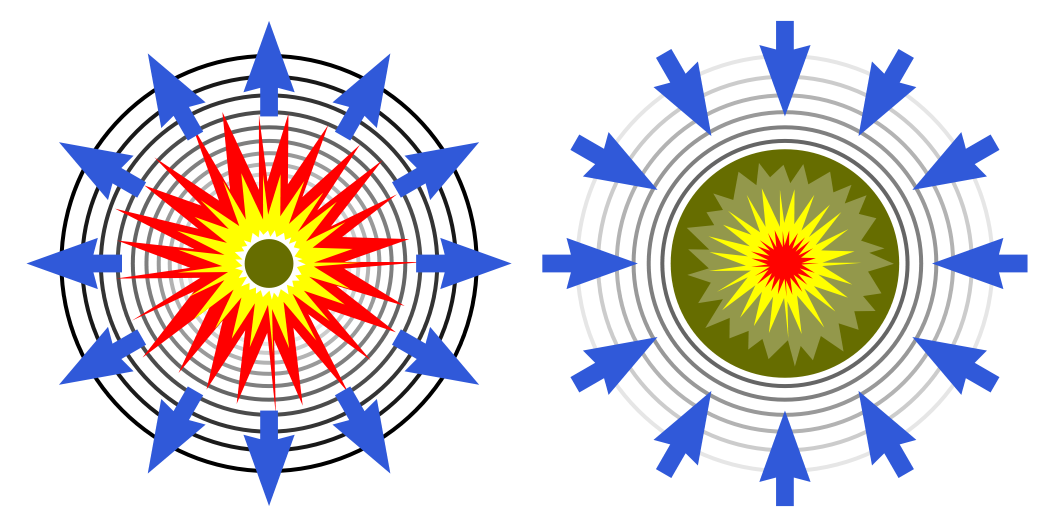

La décarbonation par l’hydrogène

L’opération consiste à injecter de l’hydrogène par l’admission d’air du moteur, provoquant de mini implosions qui décalaminent en profondeur, sans démontage et sans additif chimique ou corrosif, afin d’éliminer efficacement la calamine.

Ce procédé est totalement sécurisé et ne présente aucun risque d’explosion, l’hydrogène étant consommé instantanément sans stockage.

Le parcours de l’hydrogène assure la régénération complète de toutes les pièces du moteur (FAP, turbo, tête des injecteurs, soupapes, cylindres, etc.). Grâce à une puissance de 5600 W, notre technologie permet de traiter aussi bien les parties chaudes que froides du moteur, sur des cylindrées allant jusqu’à 60 000 cm³.

Nos champs d’actions

*Vidéo réalisée par caméra thermique infrarouge thermographique 1200°c

Explosion / *Implosion

FAP

Vanne EGR

Moteur

Turbo

🔍 Crit’Air & HydroEcotech

L’arrêté du 21 juin 2016 classe les véhicules selon leur niveau de pollution (vignette Crit’Air).

HydroEcotech aide les motorisations thermiques à réduire leurs émissions pour mieux répondre aux exigences des zones à faibles émissions (ZFE).

Exemple de décarbonation sur site

Pourquoi décarboner

votre véhicule ?

Si la calamine n’est pas éliminée régulièrement, la consommation de carburant augmente et les pièces s’encrassent, ce qui empêche le moteur de fonctionner et de respirer correctement, une étude montre que 75% des pannes sont liées à l’encrassement.

Un nettoyage du moteur en profondeur est donc une alternative primordiale pour éviter le remplacement des pièces mécaniques onéreuses et permet la baisse de consommation exorbitante de carburant. Un moteur non dépollué provoquerait dans le temps une immobilisation du véhicule et coûts extrêmement élevés de remplacement des pièces

*Frais de déplacement à partir de 99€

d’économies de carburant minimum par plein

La calamine et les causes

Pollution

Lorsque vous utilisez votre véhicule, il laisse des dépôts d’oxydation noirâtres (calamine) déposés dans des endroits stratégiques du moteur sur les parois de l’échappement.

Encrassement moteur

L’encrassement du moteur est essentiellement dû aux conditions de circulations d’aujourd’hui, avec les démarrages fréquents, avec la chaleur environnante elle ce cristallise pour former de la suie et des dépôts charbonneux, les démarrages fréquents, limitations de vitesse, la qualité des carburants, et les conduites à bas régime, des arrêts fréquents.

Les symptômes d’un moteur encrassé sont le plus souvent : la perte de puissance, un ralenti irrégulier, fumée excessive, surconsommation, allumage intempestif du voyant gestion moteur etc.

Quels sont les symptômes ?

–>Démarrage difficile

–>Voyant éclairé au tableau de bord

–>Troue à l’accélération

–>Petit trajet et arrêt fréquent

–>Baisse de performance

–>Passage en mode dégradé en moins de 3000 tours minute

Tous ses symptômes empêchent le moteur de fonctionner correctement, le pénalise fortement et lui faire perdre sa longétivité.

Simulateur

Vos économies calculées en 2 min !

Estimez votre consommation et les gains réalisées grâce à notre générateur HybridOgen®.

Simulateur d'économies

Calculez vos économies réalisées avant et après notre intervention.

RÉSULTATS DES EXPÉRIENCES DE LA NASA AVEC L’HYDROGÈNE

Nos Formations

🎓 HydroEcotech Academy

Le centre de formation de la transition énergétique

HydroEcotech Academy est le centre de formation dédié aux utilisateurs, partenaires et franchisés de nos solutions. Elle transmet notre expertise sur les technologies HybridOgen®, Go-Stop® et Dolphin, en couvrant l’installation, l’exploitation, la maintenance, le monitoring carbone et les bonnes pratiques de décarbonation.

L’objectif : former des professionnels qualifiés pour une transition énergétique efficace et maîtrisée.

Formation Décarbonation

Maîtrisez le décalaminage par hydrogène pulsé par I.A !

Technologie brevetée et en cours de certification par le Ministère des Transports et les bureaux Veritas